The Original PPI Samplers

For years, cyclones were the sampler used to collect respirable dust including respirable crystalline silica. While cyclones got the job done with an acceptable level of bias, this study and others have shown that the sampling characteristics of cyclones do not follow the entire ISO 7708/CEN curve accurately. In addition, cyclones can be inconvenient for the worker to wear and are top heavy—prone to tipping, which can invalidate the sample.

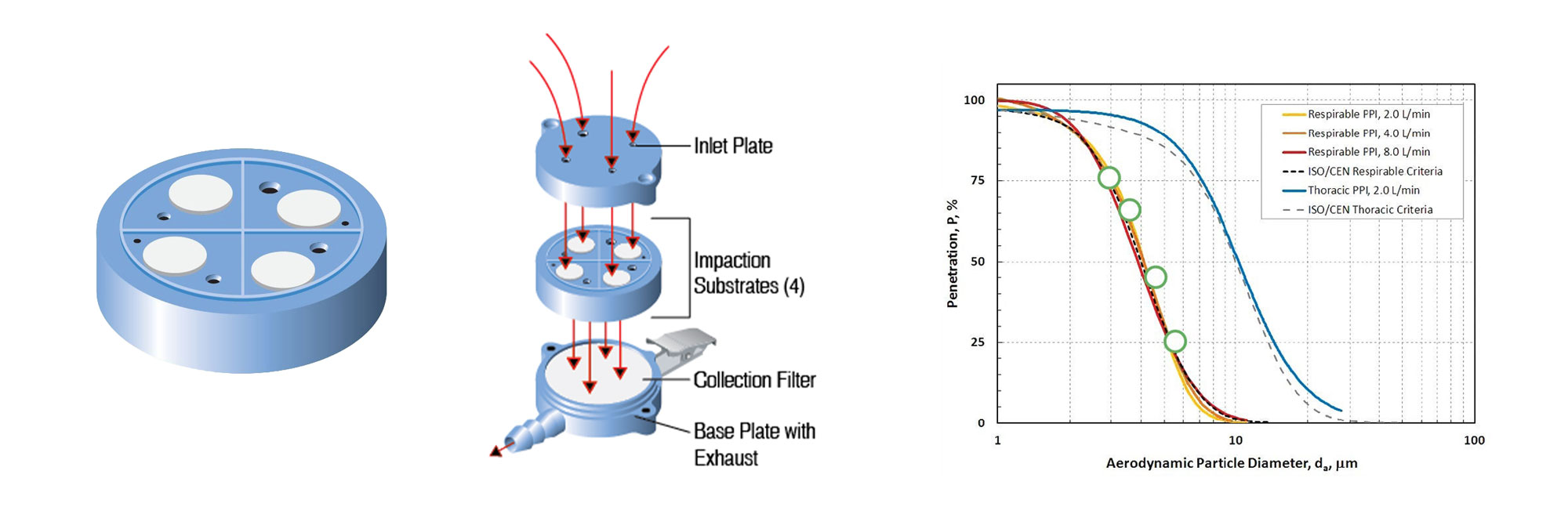

Through careful design, the patented* SKC Parallel Particle Impactor (PPI) Samplers provide the most precise match to the ISO 7708/CEN criteria and overcome the tipping invalidation experienced with traditional cyclones. Impaction-based PPI Samplers each contain four parallel impactors. Each impactor’s nozzle has been precision engineered and machined for a cut-point that matches a point on the ISO 7708/CEN respirable dust curve for a close match over the entire criteria. The proof is in the PPI performance!

SKC PPI Samplers meet the ISO 7708/CEN criteria referenced across Australian respirable dust and crystalline silica monitoring guidelines, giving you confidence that your program aligns with national expectations for WHS compliance.

With PPI technology, you can rely on consistent, high quality data that helps protect workers and strengthens your organisation's commitment to safe operations.

When your work demands accurate respirable dust or crystalline silica measurements, choose original PPI Samplers for trusted performance, precision and sampling ease. SKC PPIs are ideal for helping to keep workers safe and perfect for safeguarding your operations against regulatory risks. When you need highly accurate sampling of respirable dust or are performing compliance silica sampling, always choose original PPI Samplers for precision, accuracy, and ease.

How the PPI Sampler Works

Every impaction based PPI Sampler comprises of four precisely engineered impactors arranged in parallel, with a collection filter positioned directly beneath them. These components sit within a durable sampler body available in either disposable anti static plastic or reusable conductive aluminium.

Incoming air passes through precisely engineered and machined impactor nozzles, each designed with a unique 50 percent cut point that captures a specific quarter segment of the ISO CEN curve.

As the airflow moves through the sampler, particles larger than each impactor’s 50 percent cut point are trapped on the pre oiled impaction substrates within the impactors. Smaller particles continue to the standard 37 mm collection filter (backed by a support pad) , supported by a backing pad, in the sampler’s base plate. This filter is sent to the laboratory for analysis, which can be performed gravimetrically or chemically.

Tipping/Sample Invalidation: How PPI Samplers Address Cyclone Inversion Issues

Issue:

With traditional cyclone samplers, particles larger than the device’s cut-point fall out of the airstream and collect in a grit pot, while the respirable fraction is deposited on the filter inside the attached cassette. Problems arise when the cyclone becomes dislodged from the worker’s collar, is removed because it feels cumbersome, or is accidentally inverted during post-sampling handling. In any of these situations, the larger particles in the grit pot can fall back onto the filter, contaminating the sample. Once this occurs, the sample is invalid and must be discarded and repeated. An even bigger issue arises when an unnoticed inversion allows a compromised sample to reach the lab, affecting the accuracy of the reported exposure levels.

Solution:

PPI Samplers are designed to avoid this failure entirely. Instead of using a grit pot where oversized particles can shift, they capture particles above the cut-point on secure impaction substrates that keep them fixed in place - even if the sampler is tilted or inverted. This prevents larger particles from reaching the filter, protects sample integrity during use and handling, and reduces the need for repeat sampling while improving confidence in exposure results.

Three Flow Rates Available

Three PPI models are available, each designed for a specific flow rate of 2, 4, or 8 L/min supplied by a constant flow sampling pump for high accuracy. This provides you flexibility when work tasks or sampling durations vary and when increased limit of detection (LOD) is required, particularly during shorter sampling periods.

PPI Sampler Support Documents

Disposable PPI Sampler Datasheet

Reusable PPI Sampler Datasheet

For further information on the SKC PPI Sampler, please contact your local Air-Met Scientific team.

Impaction based sampling, precisely matched to ISO 7708/CEN criteria. Request a FREE sample today.